Menu

(410) 718-3131

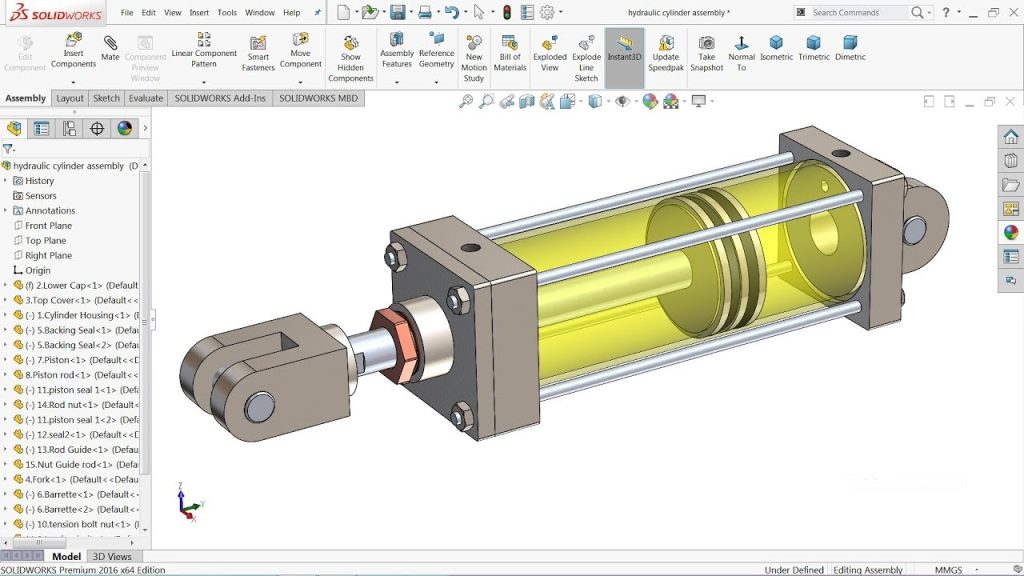

Hydraulic Cylinder Design & Optimization

Hydraulic Cylinder Design & Optimization

Hydraulic Cylinder Design & Optimization – We engineer custom hydraulic cylinders for various industrial applications, ensuring optimal performance, load capacity, and durability.

Our designs consider critical factors such as:

- Pressure Ratings & Load Capacity – Designed to withstand operating pressures up to 15 000 PSI+, ensuring structural integrity under high loads.

- Seal Integrity & Friction Optimization – Selection of high-performance sealing systems (PTFE, polyurethane, nitrile or Viton-based seals) to minimize internal leakage and reduce friction, improving efficiency and longevity.

- Stroke Length & Bore Sizing – Precise calculations for bore diameter, rod diameter, and stroke length to achieve required force output and velocity while preventing buckling or instability.

- Mounting Configurations & Alignment Considerations – Engineering of clevis, trunnion, flange, and spherical bearing mounts to handle axial and radial loads while ensuring proper alignment to prevent side loading and premature wear.

- Material Selection & Corrosion Resistance – Use of hardened steel, stainless steel, or coated materials such as chrome-plated rods to withstand harsh operating environments, including high moisture, chemicals, and abrasive conditions.